Blast Chilling and Blast Freezing Units MSD, MSS

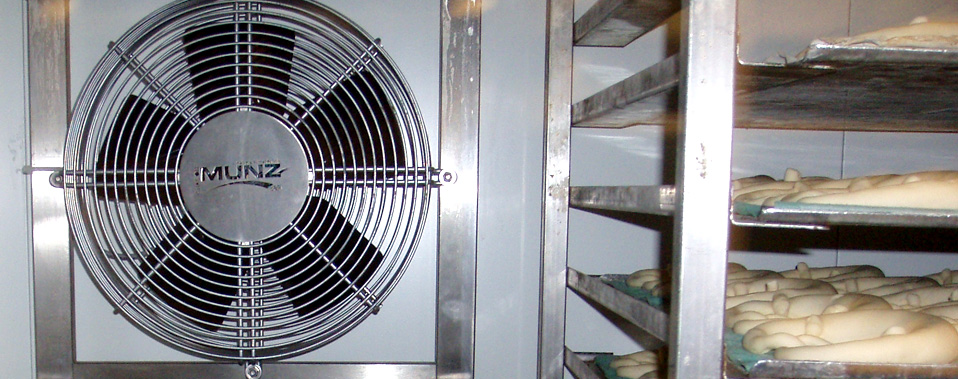

In the food processing industry blast chilling and blast freezing plays an essential role during many conservation and production processes. Munz provides suitable blast chilling and blast freezing technology for various products and production processes. Installations with evaporators on floor, loadable with rack trollies provide very high output per hour by using the tunnel system. The parking bay system enables very high flexibility with different freezing times for different products in one single device at the same time. Hereby ceiling evaporators - MSD Installation – or evaporators on floor – MSS Installation – are used depending on the requirements. Munz blast chillers and blast freezers guarantee a consistently high product quality and relieve subsequent refrigerated warehouses. Conditioning parameters like air temperature, relative humidity and air velocity will be exactly adjusted individually to the product.

Standard specifications of Munz blast chilling and blast freezing systems

| Munz designation | refrigeration technology | safety refrigerant | room temperature | relative humidity |

|---|---|---|---|---|

| MSS, MSD | single-stage cooling unit | R507A | - 18 °C to - 28 °C | 85 to 95% r. H. |

| MSS, MSD | two-stage cooling unit | R507A | - 18 °C to - 28 °C | 85 to 95% r. H. |

Comparison of blast chilling and blast freezing systems loadable with rack trollies

| feeding | ceiling evaporator | evaporator on floor | |

|---|---|---|---|

| tunnel system | advantages | high output per hour low space requirement easy integration of an rack trolly conveyer system possible |

very high output per hour easy integration of an rack trolly conveyer system possible |

| disadvantages | output per hour not as high as using an evaporator on floor fixed cycle time low flexibility |

higher space requirement fixed cycle time low flexibility |

|

| parking bay system | advantages | high output per hour high flexibility cycle time can be adjusted to the product low space requirement |

|

| disadvantages | more “thinking along” by the operator necessary |